Laminated glass

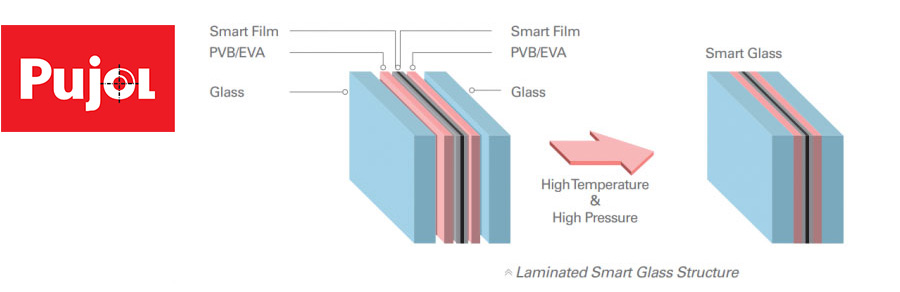

This is a process in which two or more glass sheets are glued to one another by a vacuum, with EVA safe foil embedded between them. As a result of this process, when the glass is broken, the individual pieces remain attached to each other, which makes the laminated glass sound and safe.

Today, laminated glass is produced by bonding two or more layers of ordinary float glass with a plastic inner layer, usually of polyvinyl butyl (EVA). The film is placed between the panes, which are then heated from 100 to 130°C.

Benefits of using laminated glass

Being that it is a durable and versatile glazing material, laminated glass provides better protection against UV rays. Laminated glass serves as a guard for delicate plants, fabrics, carpets and furniture from fading.

Noise gains the easiest entry to homes and buildings through windows. The usage of laminated glass has been proven to be an excellent barrier in reducing unwanted noise and sound.

Utilizing laminated glass in office workspaces can reduce stress and enhance creativity with open natural day light poring through the windows. Using heat and light stable pigments there is an unlimited color range when combined with tinted glass and coatings. Using colored laminated glass can brighten up any work area or section off different areas of an office all the while being very easy to maintain

Laminated glass can help to reduce heat gain from sunlight and ultimately reducing air conditioning costs.

| Max. format measurements 2500 x 4600 [mm] |